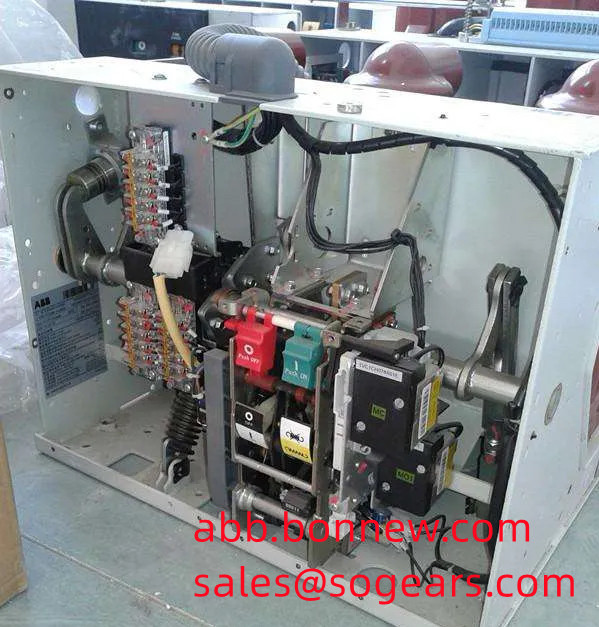

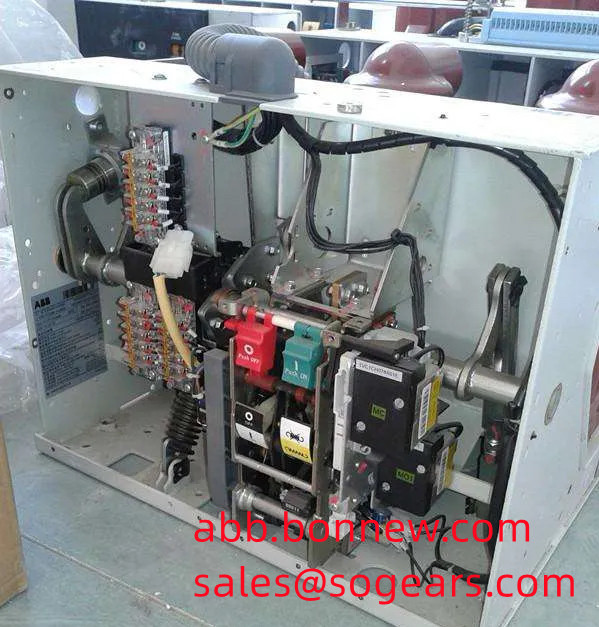

ABB brand VD4 vacuum circuit breaker is suitable for air-insulated indoor switch systems. As long as it is within the normal operating conditions and the technical parameters of the circuit breaker, the VD4 vacuum switch can meet the needs of the power grid under normal or accident conditions. operations, including closing, opening and breaking short-circuit currents. VD4 vacuum circuit breaker is the most used product in the current medium and high voltage power distribution, whether it can maintain high reliability is more and more attention by the majority of users.

Although VD4 has been tested by the global market, no matter how perfect any equipment is, there will be more or less failures with continuous use. The following is a list of common VD4 failure phenomena and equipment maintenance methods for everyone! Hope to provide you with a little help!

I. Failure of the energy storage mechanism

Fault phenomenon: Electric can not store energy, manual can store energy.

Possible causes and solutions:

1. The power supply is not connected

At this time, it should be checked whether the power supply on the terminal block of the switch cabinet is in, and whether the control switch 2ZK of the energy storage circuit is in the closing position.

2. The energy storage limit switch S1 is damaged

The energy storage limit switch S1 of the VD4-12 vacuum circuit breaker is used to control the start and stop of the energy storage motor and to connect the signal circuit, and the two pairs of the energy storage limit switch S1 are used to control the start and stop of the motor. When the normally closed (moving off) node connected in series, when the spring completes the energy storage, it drives an energy storage limit switch S1 that is mechanically linked to it, so that the normally closed contact is disconnected, the power circuit of the motor is cut off, and the motor stops charging.

After the energy is released from the spring or in the state of no e

nergy storage, the normally closed contact of the energy storage limit switch S1 should be closed, and the motor circuit should be connected to charge the spring. Therefore, you can pull out the aviation plug and measure whether the loop resistance of the 25#-35# pins is normal. If it is not normal, you should measure the normally closed contacts 31-32 and 41-42, and find that the contacts are burned out, and the energy storage limit should be replaced. switch S1. After replacing the energy storage limit switch S1, the gap of the transmission rod to be adjusted after energy storage should be 2.5-2.8mm.

3. The carbon brush of the motor is seriously worn, so that the energy storage motor cannot work normally

At this time, the motor carbon brushes should be replaced.

4. The energy storage motor MO is burned out

When the motor control circuit is complete, the motor circuit resistance can be measured. If there is any abnormality, check whether the energy storage motor is burned out. At this time, you can pull out the connecting wire, remove the three fixing bolts of the motor, take out the motor, and carry out replace.

II. The circuit breaker cannot be closed

1. The electric closing refuses to close, and the closing release does not act;

2. The electric closing refuses to close due to the weak action of the closing release, but the manual closing is successful;

3. Electric closing refuses to close, and manual closing is also unsuccessful.

For the failure phenomenon of electric closing and refusal to close, the reasons for the failure of the closing release and the treatment methods:

1. The handcart is not in place

In the case that the handcart is not shaken in place, the two travel switches of the trolley chassis cannot connect to the blocking coil circuit, so the closing circuit is also not connected, resulting in the electric closing refusal to close, and the closing release device does not act. At this time, you can observe the position indicator light or indicator on the switch cabinet, and accurately shake the handcart to the "working position" or "test position".

2. The closing and locking electromagnet Y1 is faulty

If it is the fault of the closing and blocking electromagnet Y1 or the contact of its micro switch S2 is not in place, the closing circuit will be blocked, and the electric closing will refuse to close. At this time, you can measure the resistance value of the blocking coil first. If it is not normal, if there is a short circuit or disconnection between turns of the blocking coil, you can replace the closing and blocking electromagnet module; if the resistance value of the blocking coil is normal, then check the micro Check whether the contact of the switch S2 is in place. If it is not in place, you can use needle-nose pliers to slightly move the metal shrapnel of S2 outwards by 1-2mm, drive the Y1 iron core by hand, and hear the sound of S2 action.

3. The contact of the auxiliary switch S3 of the circuit breaker is blocked or the pin of the aviation plug falls off

These two situations will cause the closing coil circuit to fail, and the electric closing will refuse to close. when the circuit breaker is open. If the normally closed contact of the auxiliary switch S3 is not turned on, it can be solved by adjusting the gap of the transmission rod of S3; if the pin of the aviation plug falls off, the aviation plug can be replaced.

The electric closing is refused to close due to the weak action of the closing release, but when the manual closing is successful, it may be that the closing voltage is too low or the closing coil can first check whether the power supply is normal, and then detect the rectifier bridge of the closing coil. Whether the component output is normal, otherwise replace the closing coil module. Electric closing refuses to close, and manual closing is also unsuccessful.

In this case, the mechanical interlock plate of the spring mechanism is generally not reset after the trolley is shaken in place, and is stuck, resulting in the closing half shaft not being tripped, and the closing operation cannot be completed, and the closing coil will be caused after a long time. burn out. By carefully checking the condition of the mechanical interlocking plate, if the interlocking plate is deformed, the drive module can be replaced as a whole.

III. Circuit breaker rejection

The failure of the circuit breaker to open is a very dangerous situation and is classified as an "emergency failure".

The fault phenomenon is:

1. The electric opening refuses to open, and the opening release does not act;

2. The electric opening refuses to open, the opening release is weak, and the manual opening can be successful.

For the failure phenomenon of electric opening and refusal to open, the reasons for the failure of the opening release and the treatment methods:

1. The opening release Y2 is damaged

The resistance value of the Y2 coil of the opening release can be measured. If there is any abnormality, the opening coil should be replaced.

2. Poor contact of auxiliary switch S4 contact

After the circuit breaker is closed, the normally open contact of the auxiliary switch S4 should be closed. After the circuit breaker is opened, the normally open contact of the auxiliary switch S4 should quickly disconnect the opening circuit, so that the opening coil can withstand short-term energization. The normally open contact of auxiliary switch S4 is easily damaged by electric shock in the process of frequent interruption, resulting in poor contact. If the damage is not serious, the clearance of the S4 transmission rod can be adjusted. If it is serious, the auxiliary switch S4 can be replaced.

3. The wiring of the secondary control circuit is loose or the pins of the aviation plug fall off

These reasons will cause the opening control circuit to fail. Through the circuit inspection, clamp the loose connection; if the pin of the aviation plug falls off, the aviation plug must be replaced.

The above are the common faults and solutions of ABB brand VD4 vacuum circuit breakers, I hope to be helpful to your use and maintenance.